This year, Pixelabs is present at several internationally recognized events. In 2025, we’ll be heading to Germany and the UK to showcase our latest solutions and products. But before leaving Spanish soil, we couldn’t miss Advanced Factories, the benchmark trade fair and annual meeting point for industrial leaders.

Advanced Factories brings together the most innovative companies in industrial automation, robotics, digital manufacturing, and Industry 4.0 technologies. Our participation in this event is not only a reflection of our commitment to innovation but also of a clear vision: transforming industrial quality control through personalized, flexible, and scalable artificial intelligence. Most importantly, our solutions are accessible to any company seeking to optimize their processes without compromising on precision or traceability.

From Traditional Quality Control to Adaptive Intelligence

For decades, quality control has relied heavily on rigid, difficult-to-scale solutions that are highly sensitive to variations in production environments. Traditional machine vision tools—based on fixed rules, pre-set configurations, and specific cameras—have served their purpose but fall short when faced with the increasing complexity of modern industrial processes.

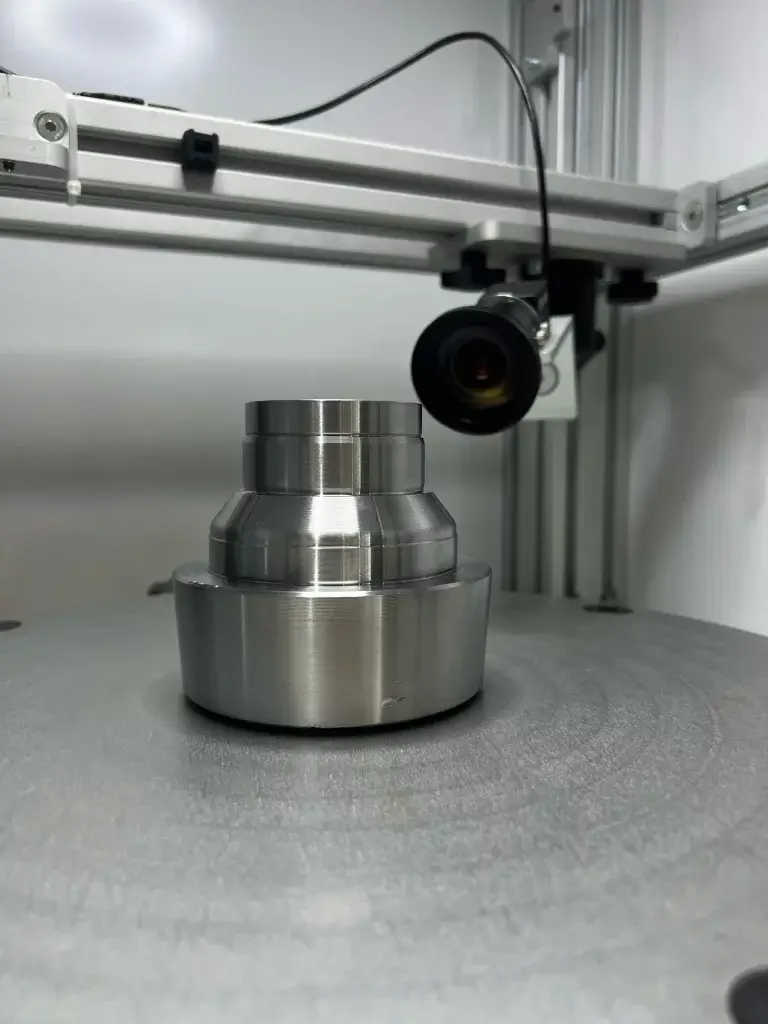

Our developments take a different approach. We’ve created a new generation of AI algorithms capable of adapting to each production line, product, and operational need—without relying on closed hardware or universal setups. The intelligence is entirely contained in our own AI-Engine, making integration possible across a wide range of environments and independent from specific image capture devices.

This paradigm shift means our solutions aren’t just more accurate—they’re also more accessible, faster to deploy, and more effective in the long term. Customization is no longer a luxury; it’s the standard. Each client benefits from a model specifically optimized for their industrial scenario.

The flexibility of our algorithms means they can analyze components of different shapes, materials, and finishes—even under variable lighting, line speeds, or physical conditions. Since they don’t rely on fixed patterns or proprietary devices, we can ensure reliable inspection even in the face of inevitable changes in real production environments.

Advanced Factories 2025: We Kick Off Q2 Surrounded by Industrial Leaders

What’s more, this customization comes with agile, ongoing training capabilities, allowing the system to learn from new scenarios, defects, and variations, improving its performance with use. Automated inspection evolves from being static to becoming a living process—one that grows with the production line.

Instead of asking production to adapt to technology, we’ve flipped the script: our technology adapts to the production. This enables our clients to scale their systems without having to redesign processes or replace existing infrastructure.

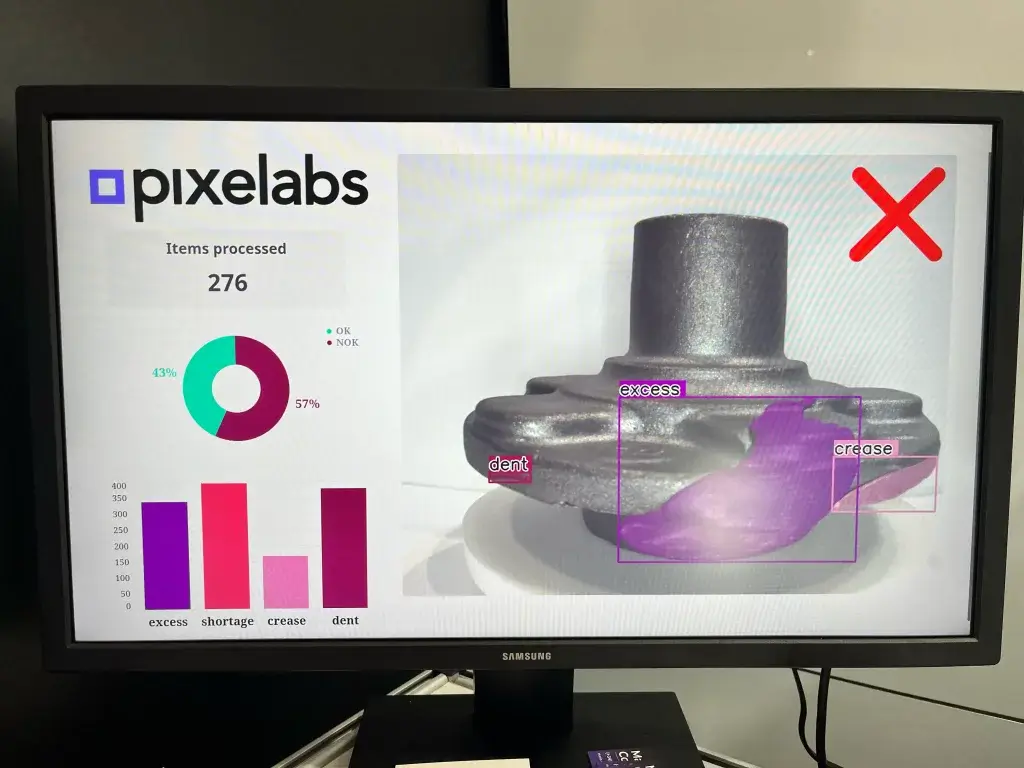

Pixelabs: computer vision quality control system.

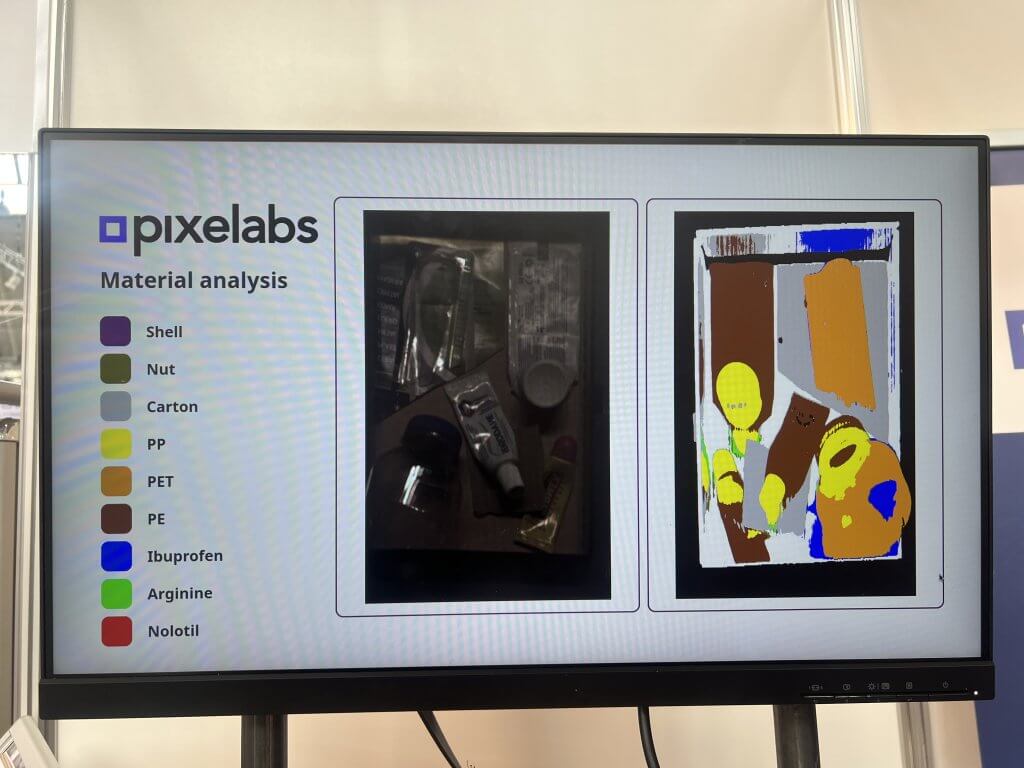

Hyperspectral Vision: Beyond the Human Eye

One of the most cutting-edge technologies we’ve incorporated is hyperspectral imaging, which can detect anomalies invisible to the human eye or traditional RGB cameras. This technique analyzes information beyond the visible spectrum, identifying material variations.

This opens up a world of possibilities in sectors where quality depends not just on the external appearance of a component, but also on its internal or compositional properties.

In the food industry, for example, hyperspectral imaging can detect foreign objects or spoiled products. In pharmaceuticals, it enables verification of the composition and uniformity of pills or capsules. In automotive and aerospace industries, it can identify both external and internal cracks, among other defects. This deep analysis capability helps prevent critical errors before they become quality or safety issues.

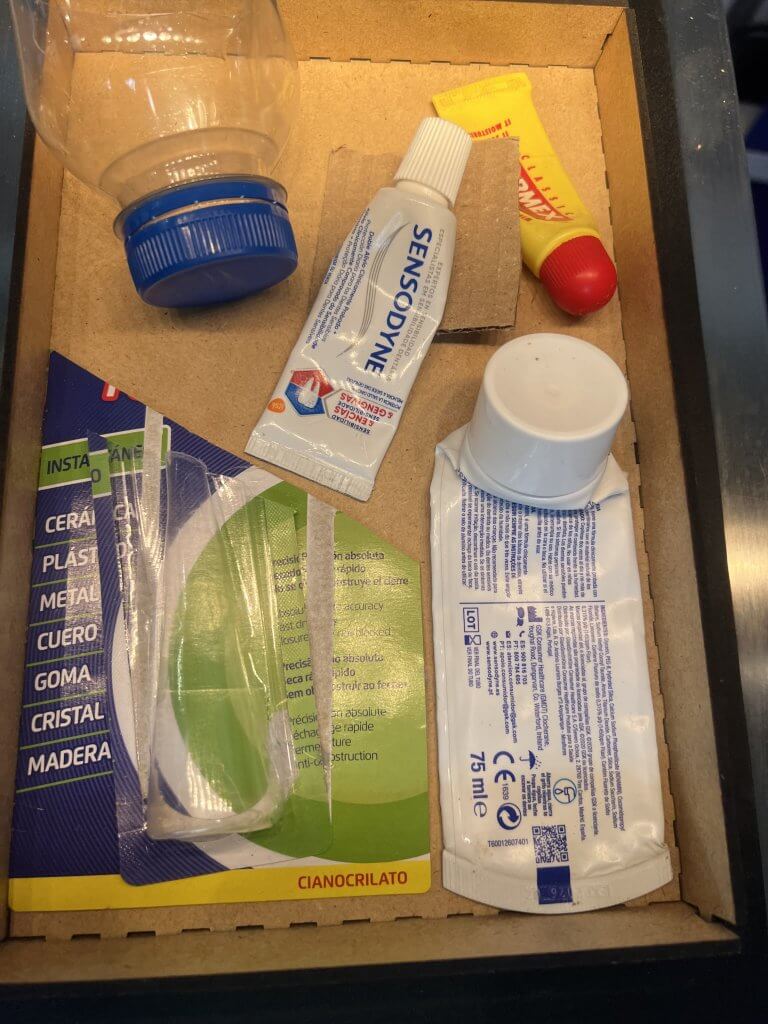

Pixelabs: hyperespectral system in real time.

Real-Time Data

Another cornerstone of our approach is traceability. Every inspected component, every detected defect, and every system decision is recorded, generating a complete historical record of the production process. This level of detail not only ensures compliance with increasingly strict regulations but also facilitates failure analysis and continuous improvement.

Our clients also gain access to personalized dashboards with real-time KPIs, empowering them to make operational decisions based on solid, up-to-date data. For instance, they can view defect rates by batch, compare performance across shifts or lines, and anticipate potential bottlenecks before they impact production.

This real-time analysis capability transforms quality inspection from a corrective task into a predictive, strategic tool—aligned with the core principles of Industry 4.0.

Want to Know How We Can Help?

If you’re looking to optimize quality control processes, improve traceability, reduce errors, and maximize efficiency in your plant, we’re ready to work with you. Whether through customized automated inspection, hyperspectral vision solutions, or real-time KPI analysis systems, we have the technology, expertise, and dedication to deliver real results.

Don’t miss out on the industrial revolution already underway. We invite you to discover our solutions, speak with our experts, and experience firsthand how artificial intelligence can transform your production.